The role of lightweight materials in modern vehicle design

Lightweight materials like aluminum, carbon fiber, and high-strength steel are revolutionizing vehicle design by boosting fuel efficiency, cutting emissions, and enhancing safety in modern cars.

Why Lightweight Materials Are Revolutionizing Vehicle Design

The automotive world has seen incredible changes over the years, especially in the materials used to build vehicles. As the demand for sustainability and fuel efficiency grows, lightweight materials have become essential in modern vehicle design. These materials not only boost fuel economy and cut emissions but also improve safety on the road. Let’s explore why lightweight materials matter so much and what the future holds for them in automotive engineering.

Unlocking the Power of Lightweight Materials in Cars

What Exactly Are Lightweight Automotive Materials?

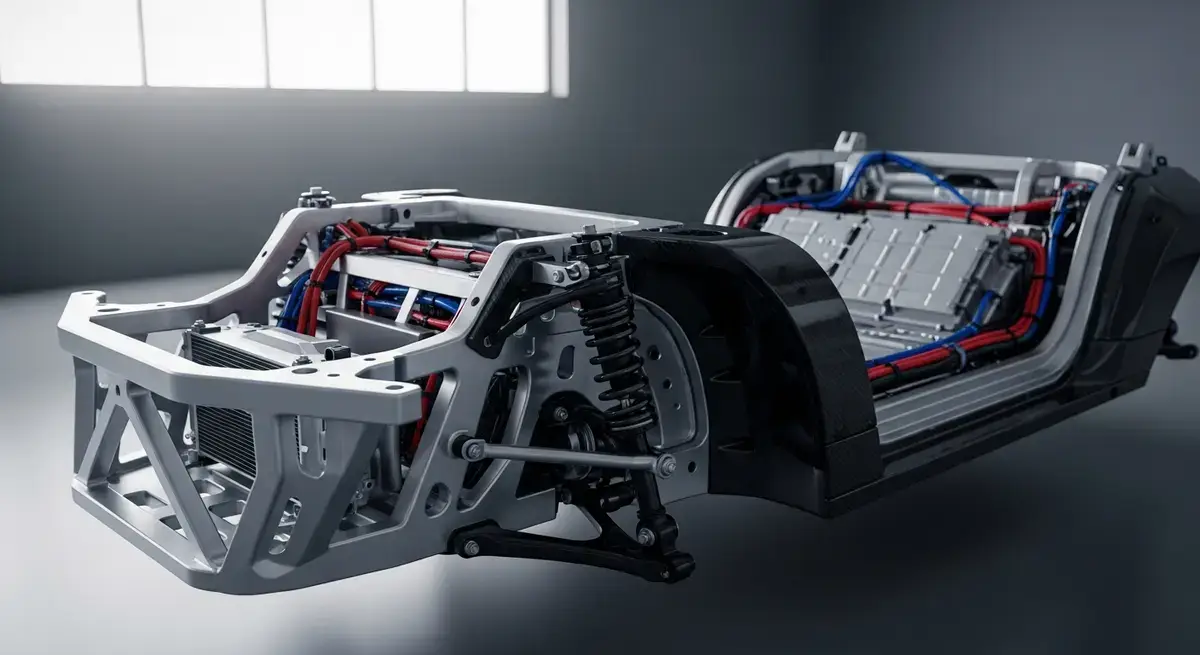

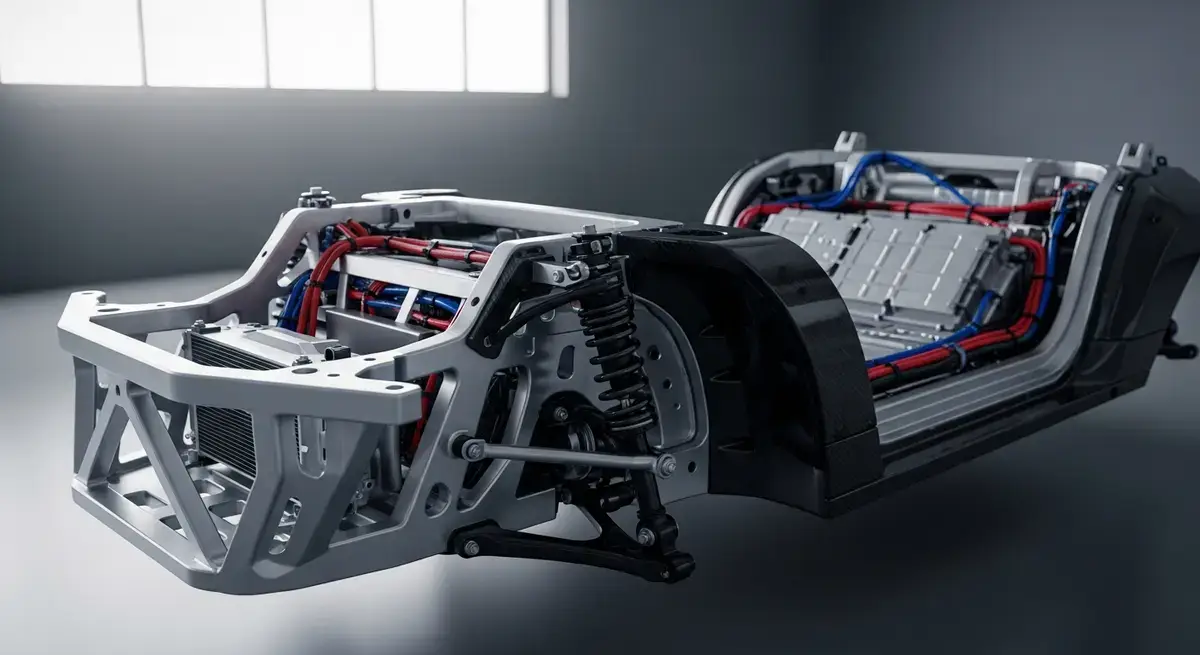

Lightweight materials are prized for their high strength-to-weight ratio, making them perfect for crafting vehicles that are both strong and efficient. By incorporating these materials, manufacturers can design cars that save fuel without compromising safety or performance.

Here are some of the most common lightweight materials transforming vehicle design today:

- Light Alloys: Aluminum and magnesium stand out for their impressive strength combined with low weight.

- High-Strength Steels: These steels offer durability while shaving off extra pounds.

- Composites: Carbon fiber and natural fiber-reinforced plastics are gaining popularity for their exceptional strength and lightweight qualities.

Using these materials isn’t just about performance—it’s a vital step toward greener, more sustainable transportation.

How Vehicle Materials Have Evolved Over Time

The shift toward lightweight materials didn’t happen overnight. Back in 1965, cars were made up of roughly 85% metals, but today, polymeric materials claim a significant portion of vehicle construction. One striking change is aluminum overtaking cast iron, a clear sign of the industry’s push toward efficiency.

This evolution reflects the automotive sector’s commitment to reducing weight, improving fuel economy, and lowering environmental impact.

How Lightweight Materials Boost Vehicle Efficiency and Safety

Save Fuel and Cut Emissions by Shedding Pounds

There’s a direct link between vehicle weight and fuel consumption. For example, trimming just 100 kg from a car’s weight can reduce fuel use by 0.3 to 0.6 liters per 100 kilometers. That adds up to big savings for drivers and a meaningful drop in CO2 emissions—especially important since road transport accounts for about 20% of global emissions.

With stricter fuel economy targets on the horizon, lightweight materials are becoming indispensable for meeting these goals.

Enhancing Safety and Performance with Advanced Materials

What Makes These Materials Stand Out?

Materials like carbon fiber reinforced plastics don’t just save weight—they bring outstanding strength and energy absorption capabilities to the table. Take the BMW i3, for instance: by using carbon fiber, it achieves significant weight reduction while maintaining top-tier safety.

Real-World Examples of Lightweight Innovation

The BMW i3 is a shining example of how lightweight materials can transform vehicle design and performance. Beyond cars, composites are also making waves in high-speed trains, proving their versatility across transportation modes.

These breakthroughs raise the bar for safety and efficiency, setting new standards for the automotive industry.

What’s Next for Lightweight Automotive Materials?

Exciting Innovations on the Horizon

The future is bright, with cutting-edge research exploring nanotechnology and natural fibers to create even lighter, stronger materials. That said, high costs—especially for materials like carbon fiber—remain a hurdle for widespread use. Overcoming these challenges will be key to the next wave of automotive innovation.

Changing How Cars Are Made

Incorporating lightweight materials means rethinking manufacturing processes and design strategies. Automakers are already adapting by developing new techniques that balance cost, efficiency, and performance. This shift is shaping the future of vehicle production.

Dive Deeper Into Automotive Material Innovations

- How technology is driving breakthroughs in automotive materials.

- Real-life success stories of lightweight materials in electric vehicles.

- Assessing the environmental impact of today’s vehicle designs.

By embracing lightweight materials, the automotive industry is steering toward a future that’s cleaner, safer, and more efficient—one innovation at a time.

Derek Shaw

Derek demystifies the complex world of global logistics. He writes about everything from warehouse automation to last-mile delivery, providing businesses with strategies to improve efficiency, leverage technology, and build a resilient supply chain.

More Related Posts

The role of lightweight materials in modern vehicle design

Lightweight materials like aluminum, carbon fiber, and high-strength steel are revolutionizing vehicle design by boosting fuel efficiency, cutting emissions, and enhancing safety in modern cars.

How AI is revolutionizing automotive quality control

Discover how artificial intelligence is revolutionizing automotive quality control with smarter inspections, predictive maintenance, and digital twins—boosting defect detection and manufacturing efficiency.

The future of sustainable manufacturing in the auto industry

Discover how the automotive industry is driving sustainability with eco-friendly materials, circular economy principles, and innovative manufacturing to cut emissions and meet green consumer demand.

Key cybersecurity challenges for connected vehicles

Connected vehicles face growing cybersecurity risks due to constant data exchange and V2X communication. Learn key challenges and strategies to protect privacy, ensure safety, and secure the future of smart transportation.