How AI is revolutionizing automotive quality control

Discover how artificial intelligence is revolutionizing automotive quality control with smarter inspections, predictive maintenance, and digital twins—boosting defect detection and manufacturing efficiency.

How Artificial Intelligence is Revolutionizing Quality Control in the Automotive Industry

In today’s fast-evolving automotive landscape, quality control is more critical than ever to ensure vehicles meet rigorous safety and performance standards. As cars become increasingly sophisticated, packed with cutting-edge technology and complex systems, traditional quality control methods are being pushed to their limits. Artificial intelligence is stepping in to transform these processes, bringing smarter, faster, and more precise solutions to the manufacturing floor.

The Journey of Quality Control in Automotive Manufacturing

From Manual Inspections to Modern Challenges

For decades, automotive quality assurance depended largely on manual visual inspections, functional testing, and random sampling. While these methods served their purpose, they struggle to keep up with the growing complexity of today’s vehicles, which now feature intricate electronics and software systems. Human inspectors face limitations like fatigue and difficulty spotting tiny defects—issues that can compromise overall quality.

Why Change is Essential

Modern vehicles often contain over 100 million lines of code, making the manufacturing process vastly more complex. Traditional quality control methods can’t effectively detect every flaw, leading to costly recalls and safety risks. To keep pace with innovation and ensure reliability, the automotive industry must embrace new, AI-powered approaches.

How AI is Transforming Quality Control for the Better

Smarter Inspections with Machine Learning

AI-driven inspection systems analyze data in real time, dramatically boosting the accuracy of defect detection. Studies show AI can improve defect identification by up to 30% compared to conventional methods, enabling manufacturers to catch issues early and reduce costly rework.

Cutting-Edge Defect Detection Technologies

By combining computer vision with machine learning, automakers are revolutionizing how defects are spotted on the assembly line. For example, industry giants like BMW and Audi use AI to inspect welds and identify imperfections with remarkable precision, improving both quality and efficiency.

BMW’s Data-Driven Quality Boost

BMW harnesses machine learning algorithms to sift through massive datasets, detecting defects earlier than ever before. This proactive approach minimizes waste and elevates product quality, showcasing the power of AI in real-world production.

Predictive Maintenance: Keeping Machines in Top Shape

AI isn’t just about catching defects—it also helps prevent them by predicting when equipment might fail. By analyzing sensor data, AI can reduce maintenance costs by as much as 80%, cutting downtime and keeping production lines running smoothly.

Digital Twins: The Virtual Revolution in Quality Control

Building Virtual Vehicle Models

Digital twins are virtual replicas of physical cars that simulate how they perform under different conditions. This technology allows manufacturers to test and optimize designs without building physical prototypes, accelerating development timelines by up to 65% and giving companies a competitive edge.

Unlocking Continuous Improvement with AI Insights

Data from digital twins provides deep insights that help refine quality control processes over time. This ongoing feedback loop empowers manufacturers to enhance vehicle safety and reliability continuously.

Real-World Success Stories and Industry Leaders

How Top Automakers Are Leading the AI Charge

Companies like Tesla, Ford, and Volkswagen are pioneering AI integration in quality control, from automating inspections to using generative AI for design improvements. Their innovations set benchmarks that are reshaping the entire automotive industry.

What the Future Holds

Experts predict that by 2025, over half of automotive companies will have adopted AI technologies in manufacturing. This rapid adoption highlights AI’s vital role in driving quality and efficiency forward.

Navigating Challenges on the Road to AI Adoption

Bridging the Skills Gap

As AI becomes central to quality assurance, there’s a growing need for professionals skilled in embedded systems and safety standards. Without this expertise, companies risk relying too heavily on automation without the critical human oversight necessary for nuanced decision-making.

Balancing Automation with Human Expertise

While AI offers tremendous advantages, the best results come from a partnership between intelligent systems and skilled quality assurance teams. Human judgment remains essential to interpret complex scenarios and maintain high standards.

AI is not just enhancing quality control—it’s reshaping the entire automotive manufacturing ecosystem. By combining advanced defect detection, predictive maintenance, and digital twin technologies, the industry is moving toward a future where vehicles are safer, more reliable, and built with unprecedented precision. Stay tuned as AI continues to drive innovation and elevate the standards of automotive quality.

Alex Ryder

Alex lives and breathes cars. He delivers engaging, hands-on reviews of the latest models, combining technical knowledge with a pure passion for the driving experience. His articles are for enthusiasts who want to know how a car truly feels on the road.

More Related Posts

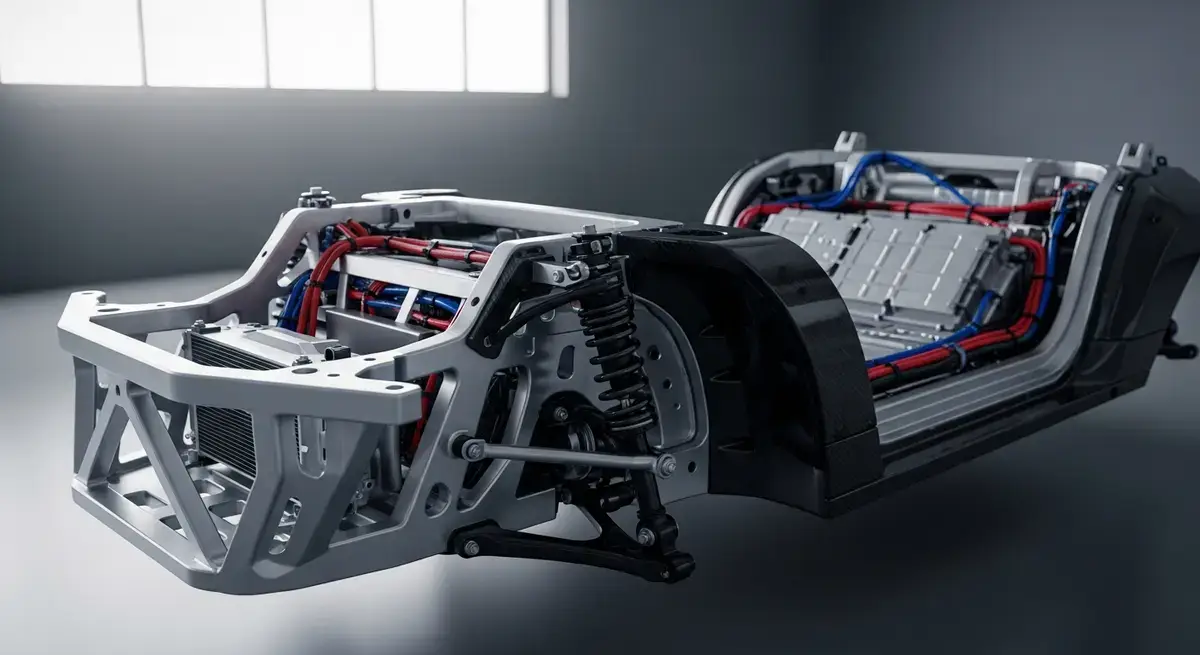

The role of lightweight materials in modern vehicle design

Lightweight materials like aluminum, carbon fiber, and high-strength steel are revolutionizing vehicle design by boosting fuel efficiency, cutting emissions, and enhancing safety in modern cars.

How AI is revolutionizing automotive quality control

Discover how artificial intelligence is revolutionizing automotive quality control with smarter inspections, predictive maintenance, and digital twins—boosting defect detection and manufacturing efficiency.

The future of sustainable manufacturing in the auto industry

Discover how the automotive industry is driving sustainability with eco-friendly materials, circular economy principles, and innovative manufacturing to cut emissions and meet green consumer demand.

Key cybersecurity challenges for connected vehicles

Connected vehicles face growing cybersecurity risks due to constant data exchange and V2X communication. Learn key challenges and strategies to protect privacy, ensure safety, and secure the future of smart transportation.